Engineering Plastic Machining

Precision-crafted plastic components for your industry needs...

Precision Engineering Plastic Machining

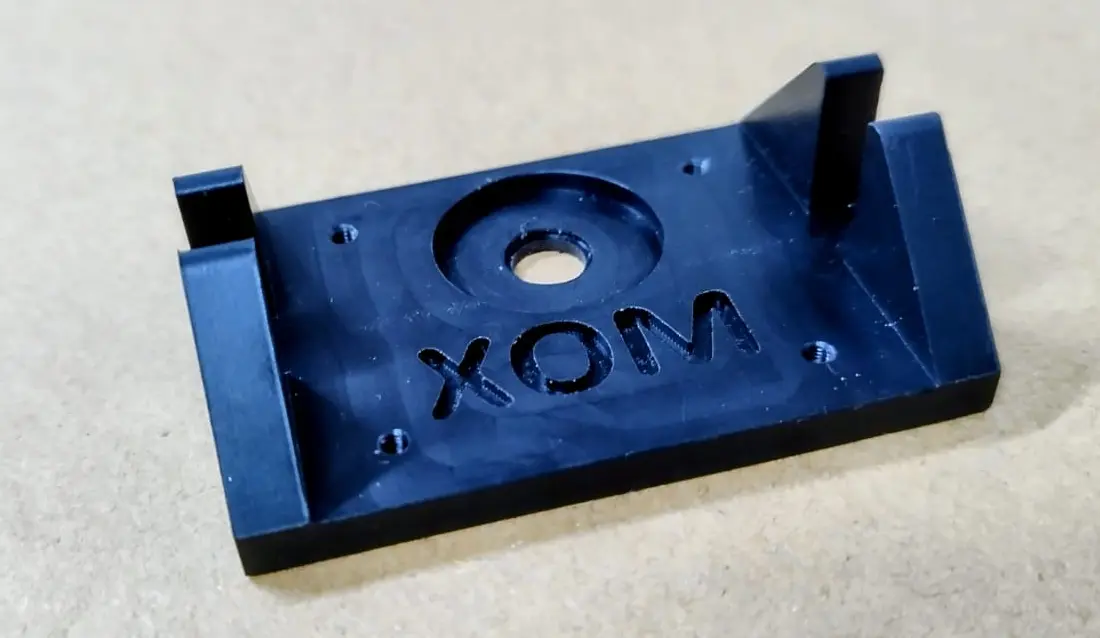

Precision Machining for High-Performance Plastics – Delivered by Project Nation

At Project Nation, we specialize in the precision machining of engineering plastics used across demanding industries such as automotive, aerospace, medical devices, packaging, and electronics.

With our deep experience in CNC milling, turning, and routing of advanced polymers, we deliver tight-tolerance parts built for strength, chemical resistance, and long-term performance.

CNC Turning & Milling

- 3 and 4 CNC milling enables intricate contours, complex undercuts, and precise pocketing on plastics like PEEK, Delrin, and polycarbonate. These technologies support high repeatability and excellent surface finish.

- Ideal for flat or prismatic components such as panels, housings, and mechanical fixtures.

Routing & Profiling

- Laser cutting, Routing & waterjet cutting offer burr-free edges and negligible heat-affected zones—great for delicate parts, composite plastics, and thin sheets.

- Hot-knife & saw cutting, although traditional, remain essential for prototyping, foam-core panels, or quick-turn sheet fabrication.

- Ideal for flat components and custom panels.

Threading, Drilling, Slotting

- Implement deep-hole drilling, helical tapping, and thread milling for inserts, fastener slots, and precise joining points on components.

- Strategic machining parameters prevent cracking or material pull-out, particularly in brittle or fiber-reinforced plastics

-

Precision secondary operations per drawing or spec.

Materials We Machine

Material | Properties | Applications |

|---|---|---|

| Polypropylene (PP) | Lightweight, chemical-resistant | Automotive parts, packaging |

| PEEK | High strength, heat-resistant | Aerospace, medical implants |

| Acrylic | Transparent, UV-stable | Displays, lenses |

| Nylon | Durable, low friction | Bearings, bushings |

| CIBA | High-performance, chemical-resistant | Industrial components |

Our Commitment to Quality

Project Nation adheres to the highest standards of quality, ensuring every component meets your specifications. Our processes include:

- Advanced inspections using CMM and optical comparators.

- Tight tolerances down to ±0.01 mm for critical applications.

- ISO 9001:2015 certified quality management system.

- Full material and process traceability.